Issues

Charging Infrastructure

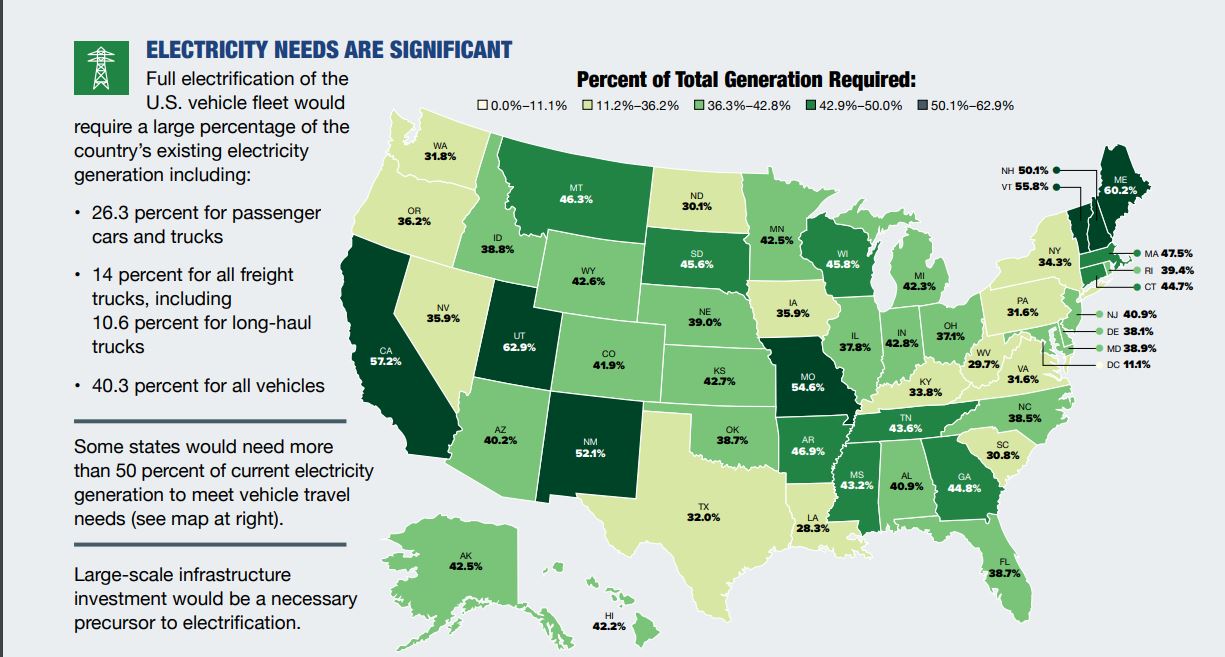

According to the American Transportation Research Institute (ATRI), large-scale infrastructure investment remains a precursor to electrification.

Full electrification of the U.S. vehicle fleet would require a large percentage of the country’s existing electricity generation, including:

- 26.3% for passenger cars and trucks

- 14% for all freight trucks, including 10.6 percent for long-haul trucks

- 40.3% for all vehicles

Some states would need more than 50 percent of current electricity generation to meet vehicle travel needs.

Supply Chain Electrification

A March 2024 report for the Clean Freight Coalition finds that full electrification of the U.S. commercial truck fleet would require nearly $1 trillion in infrastructure investment alone. Preparing today’s commercial vehicle fleet for electrification would cost upwards of $620 billion of investment in charging infrastructure alone, including chargers, site infrastructure, and electric service upgrades.

This same report finds that:

- Utilities would need to invest $370 billion to upgrade their grid networks to meet the demands of just commercial vehicles.

- This nearly $1 trillion expenditure does not account for the cost of new battery-electric trucks, which according to market research can be two to three times more expensive than their diesel-powered equivalents. For example, a diesel Class 8 truck costs roughly $180,000, while a comparable battery-electric truck costs over $400,000.

- While medium-duty vehicles will face fewer roadblocks, economic and operational constraints make electrification very challenging for the heavy-duty segment, and significant improvements in battery range and charging infrastructure capabilities would be needed to support a path for the electrification of long-haul vehicles.

Zero Emission Technology

Battery Materials Dominate Battery Electric Vehicle (BEV) Viability

Tens of millions of tons of cobalt, graphite, lithium, and nickel will be needed to replace the existing U.S. vehicle fleet, placing high demand on raw materials. Depending on the material, this represents:

- 6.3 to 34.9 years of current global production.

- 8.4 to 64.4% of global reserves.

BEV production has considerable environmental and social impacts:

- Mining and processing produce considerable CO2 and pollution issues.

- In some operations, a minimum of one million gallons of water must be utilized to produce a single pound of lithium.

- Exploitation of labor is common in some source countries.

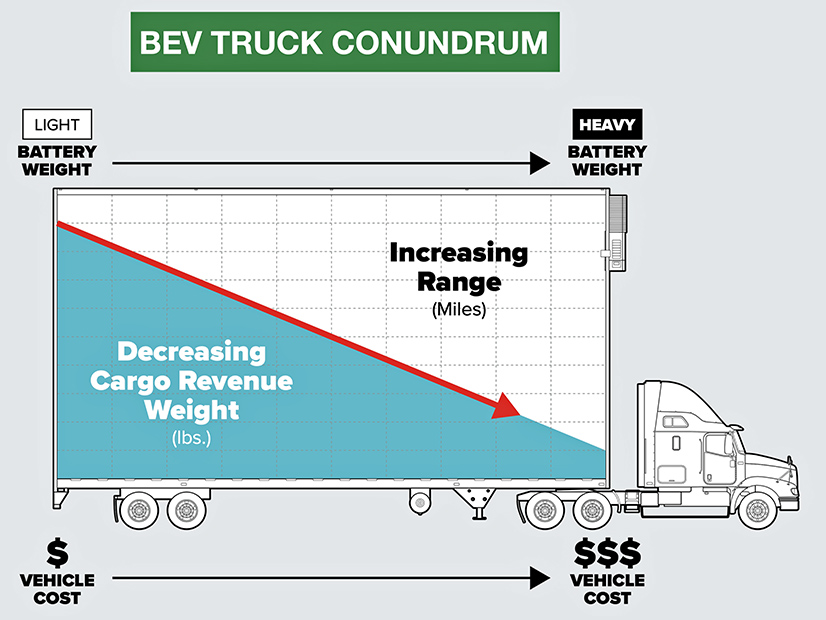

BEV Truck Conundrum

Battery weight increases price and vehicle range but decreases cargo revenue weight. Ultimately, more BEV trucks will be needed on already congested roadways to haul the same amount of freight.